In today's demanding industrial landscape, the efficiency and purity of processes hinge significantly on superior filtration. From safeguarding sensitive machinery to ensuring product integrity, advanced filtration solutions are indispensable. Our focus today is on the Woven Wire Mesh Filter Tube / Filter Cartridge, a cornerstone in countless applications. This versatile component plays a pivotal role in systems requiring robust and reliable particulate removal. The market sees a growing demand for specialized solutions, including brass mesh filter, custom metal mesh filters, and inline stainless steel mesh filter, each tailored to specific operational challenges. Understanding their unique attributes and applications is key to optimizing industrial performance and compliance.

The drive for higher purity standards and environmental compliance is accelerating innovation across the filtration sector. Industries are constantly seeking solutions that offer enhanced performance, extended service life, and reduced maintenance. This demand fuels the development of advanced materials and manufacturing techniques for components like the filter metal mesh and filter steel mesh. Our expertise lies in delivering filtration elements that meet these stringent requirements, providing unparalleled protection for equipment and ensuring the quality of end products. From standard offerings to complex custom metal mesh filters, we empower industries to achieve their operational goals with confidence.

Understanding Woven Wire Mesh Filter Tubes and Cartridges

Product Overview: Woven Wire Mesh Filter Tube / Filter Cartridge

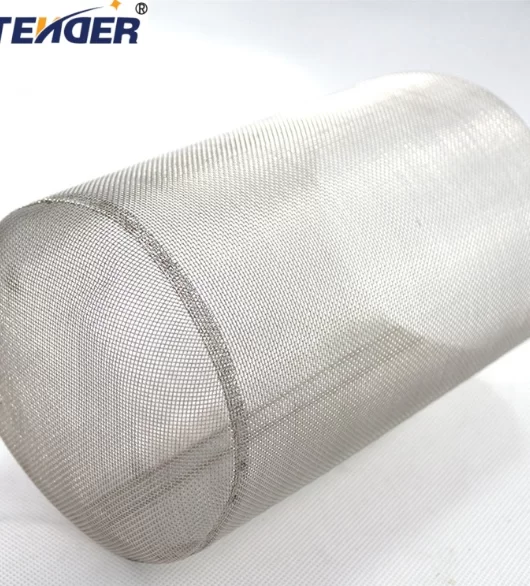

The Woven Wire Mesh Filter Tube / Filter Cartridge is a precisely engineered cylindrical filter element, typically formed by rolling, welding, or edging stainless steel woven metal wire mesh. Characterized by its simple yet robust structure and strong permeability, it excels in applications requiring primary filtration and protection for equipment or pipeline systems against particulate impurities in liquids or gases. Its widespread adoption spans critical sectors such as petroleum, chemical, pharmaceutical, water treatment, food, and machinery, underscoring its versatility and effectiveness.

The design principle of these filters leverages the inherent strength and consistent pore size of woven wire mesh. This construction ensures efficient particle capture while maintaining optimal flow rates, a crucial balance for preventing system blockages and extending the lifespan of downstream components. Whether it's a fine mesh filter protecting sensitive analytical instruments or a more robust filter metal mesh safeguarding heavy industrial pumps, the core function remains consistent: reliable separation of solids from fluids. Our offerings are meticulously designed to provide superior performance and durability in even the most challenging operating environments.

Diverse Applications Across Industries

The adaptability of woven wire mesh filters translates into a vast array of applications across diverse industrial sectors. For instance, in the petrochemical industry, robust filter steel mesh and inline stainless steel mesh filter units are essential for protecting pumps, valves, and heat exchangers from catalyst fines and corrosion byproducts, ensuring continuous operation and preventing costly downtime. Similarly, pharmaceutical manufacturing relies heavily on fine mesh filter elements made from medical-grade stainless steel to achieve critical purity levels in drug formulations and sterile processing.

In water treatment, galvanised mesh filters are frequently employed for pre-filtration to remove larger suspended solids, protecting more delicate membrane systems downstream and contributing to energy efficiency by reducing pump strain. The food and beverage industry utilizes specialized filtering mesh solutions for clarifying liquids, removing sediment from fruit juices, or straining edible oils, all while adhering to strict hygiene standards. The inherent corrosion resistance of materials like stainless steel and brass, coupled with custom sizing options, ensures these filters provide long-term reliability and significant operational advantages in aggressive chemical environments or high-temperature processes.

Manufacturing Excellence: Crafting Precision Filters

The production of high-performance filter tubes and cartridges, including brass mesh filter and filter steel mesh variants, is a meticulous process demanding precision and adherence to strict quality protocols. It begins with the selection of premium raw materials, such as various grades of stainless steel (e.g., 304, 316, 316L), brass, or galvanized steel, chosen based on the intended application's temperature, pressure, and chemical compatibility requirements. The raw wire is then expertly woven into mesh, a critical step that determines the mesh count, wire diameter, and ultimately, the filtration efficiency (micron rating) and mechanical strength of the final product.

Following the weaving stage, the mesh undergoes a series of manufacturing processes. For filter tubes, this typically involves rolling the woven sheet into a cylindrical form, followed by precision welding (e.g., TIG, laser welding) or crimping/edging to secure the seam and end caps. This intricate process ensures the structural integrity and leak-proof performance of the filtering mesh. Every step, from material procurement to final assembly, is subject to rigorous quality control measures, often conforming to international standards such as ISO 9001:2015 for quality management, and ASTM E2814 for woven wire mesh specifications. This comprehensive approach guarantees that each custom metal mesh filter delivers consistent, reliable performance and an extended service life in critical applications across industries like petrochemicals, metallurgy, and water supply.

Technical Specifications & Performance Data

Comparison of Common Metal Mesh Filter Types

Filter Type | Typical Material | Key Advantage | Common Application | Temperature Range (°C) |

Brass Mesh Filter | Brass (Copper-Zinc Alloy) | Excellent electrical conductivity, good corrosion resistance to non-oxidizing acids. | Gas/liquid filtration, EMI shielding, decorative applications. | -50 to 200 |

Filter Steel Mesh | Stainless Steel (304, 316L) | High strength, superb corrosion resistance, wide temperature range, hygienic. | Chemical, food & beverage, pharmaceutical, water treatment. | -200 to 500+ |

Galvanised Mesh Filters | Galvanised Steel | Economical, good corrosion resistance in atmospheric conditions. | General industrial, agricultural, pre-filtration for large particles. | -30 to 250 |

Inline Stainless Steel Mesh Filter | Stainless Steel (304, 316L) | Integrated design for pipeline protection, high pressure resistance. | Hydraulic systems, process lines, fuel filtration. | -100 to 400 |

Fine Mesh Filter | Stainless Steel, Exotic Alloys | Precise particle separation, high surface area for fine filtration. | Precision instrumentation, laboratory, medical devices, high-purity processes. | Varies (application specific) |

Key Technical Indicators for Woven Wire Mesh Filter Tubes

To illustrate the performance of our Woven Wire Mesh Filter Tubes, consider the following representative data points. These parameters are crucial for engineers and procurement specialists to ensure optimal system integration and performance.

Parameter | Typical Range/Value | Significance |

Filtration Rating (Microns) | 5µm to 500µm+ | Defines the smallest particle size effectively removed. Crucial for fine mesh filter applications. |

Operating Pressure (Max) | Up to 10 MPa (1450 psi) | Maximum pressure the filter can withstand without deformation or failure. Essential for inline stainless steel mesh filter systems. |

Temperature Resistance | -200°C to 500°C | Range of temperatures where material integrity and performance are maintained. |

Flow Rate (per unit area) | 50-500 L/min/m² @ 0.1 MPa | Volume of fluid passing through per unit time, directly impacting system throughput. |

Material Porosity | 30-70% | Percentage of open space in the mesh, influencing flow and dirt-holding capacity. |

Note: Specific values vary based on mesh type (e.g., plain weave, twilled weave, Dutch weave), wire diameter, and material chosen for the filter metal mesh. Custom specifications are available to meet unique project demands.

Advanced Filtration Solutions: Customization and Innovation

Recognizing that off-the-shelf solutions rarely fit every industrial niche perfectly, we specialize in custom metal mesh filters. Our engineering team collaborates closely with clients to develop filtration elements that precisely match their operational parameters, whether it's for a high-viscosity liquid, an aggressive chemical, or a delicate biological process. This bespoke approach encompasses a wide range of variables, including the selection of exotic materials for extreme environments, optimization of mesh pore size for specific filtration ratings, and design of unique geometries to fit existing housings or new system integrations.

For example, a client requiring an inline stainless steel mesh filter for high-pressure cryogenic applications might need a specialized welding technique and a specific 316L stainless steel alloy for enhanced ductility at low temperatures, alongside a multi-layered mesh design for improved dirt-holding capacity without sacrificing flow. Similarly, a brass mesh filter might be customized with a specific crimp for improved rigidity in a vibratory application. Our experience in delivering such tailored solutions, often involving iterative design and prototyping, ensures that the final product not only meets but often exceeds performance expectations, showcasing our commitment to client success and innovative problem-solving.

EEAT: Trust and Authority in Filtration Solutions

Our unwavering commitment to the Google EEAT (Expertise, Experience, Authoritativeness, Trustworthiness) framework underpins every aspect of our operations. Our expertise is built upon decades of specializing in industrial filtration, particularly in manufacturing superior filtering mesh products. We employ engineers and technical specialists with deep knowledge of material science, fluid dynamics, and manufacturing processes, ensuring that every filter metal mesh solution is designed and produced to the highest standards. Our experience is reflected in thousands of successful installations globally, serving a diverse clientele from multinational corporations to niche specialized manufacturers.

Our authority in the field is substantiated by numerous industry certifications, including ISO 9001:2015 for quality management, and adherence to relevant ASTM and ANSI standards for material and product specifications. For specific applications like food processing or pharmaceuticals, our fine mesh filter products comply with FDA guidelines. We provide comprehensive test data, including micron ratings, pressure drop characteristics, and material certifications, for all our products, including galvanised mesh filters. Trustworthiness is fostered through transparent communication, a robust warranty policy, and a dedicated customer support team available to assist with technical queries, product selection, and after-sales service. Our commitment extends to providing clear delivery schedules and ensuring complete client satisfaction, reinforcing our position as a reliable partner in industrial filtration.

Frequently Asked Questions (FAQ)

Q1: What materials are commonly used for Woven Wire Mesh Filter Tubes?

A1: The most common materials include stainless steel (304, 316, 316L), known for its excellent corrosion resistance and strength. Other materials like brass mesh filter, galvanized steel, nickel alloys, and titanium are also used for specific chemical compatibilities or temperature requirements.

Q2: How do I determine the correct micron rating for my filtering mesh application?

A2: The micron rating depends on the size of the particles you need to remove and the desired purity of the fluid. It's crucial to assess the particle size distribution in your process stream and the sensitivity of downstream equipment. Consulting our technical team for a detailed analysis is recommended.

Q3: Can these filter tubes handle high-temperature and high-pressure environments?

A3: Yes, filter tubes made from stainless steel and specialized alloys are designed to withstand extreme conditions. Materials like 316L stainless steel are suitable for temperatures up to 500°C and significant operating pressures, making them ideal for filter steel mesh applications in demanding industries.

Q4: What are the benefits of choosing custom metal mesh filters over standard options?

A4: Custom filters are precisely engineered to meet unique operational demands, optimizing filtration efficiency, flow rates, and lifespan for specific applications. They can prevent system bottlenecks, reduce maintenance, and ensure perfect fitment, leading to overall cost savings and improved performance.

Q5: Are your fine mesh filter products suitable for sanitary applications?

A5: Absolutely. We offer filter elements made from sanitary-grade stainless steel (typically 316L) with polished surfaces and crevice-free designs to meet the stringent requirements of food, beverage, and pharmaceutical industries, ensuring easy cleaning and preventing contamination.

Q6: What is the typical lead time for an inline stainless steel mesh filter or custom order?

A6: Lead times vary depending on complexity, material availability, and order volume. Standard items typically ship within 2-4 weeks. For custom metal mesh filters, we provide a detailed project timeline upon design finalization, ensuring transparent communication regarding delivery.

Q7: Do you offer after-sales support and warranty for your filtration products?

A7: Yes, we provide comprehensive after-sales support, including technical assistance, troubleshooting, and maintenance guidance. All our filter products come with a standard warranty, details of which are provided with each quotation and order confirmation, ensuring peace of mind for our clients.

Conclusion: Partnering for Superior Filtration

The demand for precise and reliable filtration is an unceasing force in industrial operations. From enhancing product purity to safeguarding critical infrastructure, the role of high-quality filter solutions, especially advanced Woven Wire Mesh Filter Tube / Filter Cartridge components, cannot be overstated. By leveraging our deep expertise in materials, manufacturing, and application engineering, we deliver not just products, but comprehensive filtration strategies. Whether your need is for standard filter metal mesh or highly specialized custom metal mesh filters, our commitment to quality, performance, and client satisfaction remains paramount.

Partnering with us means gaining access to a wealth of knowledge and a track record of excellence in the filtration industry. We invite you to explore how our innovative solutions, including robust filter steel mesh and precise fine mesh filter technologies, can optimize your processes, reduce operational costs, and secure your competitive advantage. Our dedication to providing reliable, high-performance filtration ensures that your operations run smoothly, efficiently, and with the utmost integrity.

References

1. International Organization for Standardization (ISO). ISO 9001:2015 Quality management systems – Requirements.

2. ASTM International. ASTM E2814 – 11(2017) Standard Guide for Selection of Wire Cloth for Industrial Purposes.

3. United States Food and Drug Administration (FDA). Title 21 Code of Federal Regulations, Parts 170-199 (Indirect Food Additives: Polymers).

4. Perry's Chemical Engineers' Handbook. Section 18: Separation Processes (Filtration).

Контактная информация

Quick Link

Copyright © 2025 Anping Tengde Metal Wire Mesh Products Co., Ltd.All Rights Reserved. Sitemap | Privacy Policy

Please leave us a message and we will get back to you shortly.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.